Posts Tagged ‘EMC’

NexTek’s International Agent Network Continues To Expand – New Coverage For Southeast Asia!

As a part of our continued efforts to expand our Global Partner Network, we are proud to announce a new relationship with New Tech Venture which will provide coverage for the Southeast Asian region. As always, we are excited to have a leading-edge technical sales firm providing top-notch local support for customers and potential customers in…

Read MoreTechnical Sales Coverage for Australia and New Zealand – Announcement

We are happy to announce a brand-new international partner, providing Technical Sales and Support coverage for Australia and New Zealand! ASD Technology, based in Sydney and found here online: http://www.asdtech.com.au/, is an excellent Manufacturers’ Representative and we are excited to be the latest addition to the ASD Line Card! We look forward to being able…

Read MoreLionheart Northwest Joins the NexTek Sales Team – New Rep Coverage for the Pacific Northwest!

Once again, we are excited to be able to announce a new local sales representation partnership… This time providing full technical sales coverage in the Pacific Northwest states of Washington, Oregon, and Idaho. Learn more about Lionheart by visiting their website here (click the logo below!) And to learn more and see our entire list of…

Read MoreDid You Know? – NexTek EMI Filters Are Used In Medical Equipment to Prevent Unwanted Electrical Interference

Where Are These Filters Used? High Current EMI Filters are commonly used on high power feed lines within MRI Machines and high-power Medical Lasers, in order to prevent any electronic interference issues and provide full Electromagnetic Compliance to common Medical Equipment regulations. EMI Filters can be required on the Noise Source or the potential Noise Victim,…

Read MoreDid You Know? – NexTek EMI Filters Are Currently Used On Military Vehicles Worldwide!

As electronics equipment and power systems become more and more complex, dealing with EMI/RFI issues becomes more and more important. For high current (high overall system power) power systems on mobile vehicles such as those being developed for new military vehicle designs, compliance with EMI requirements is just as critical as getting the system to…

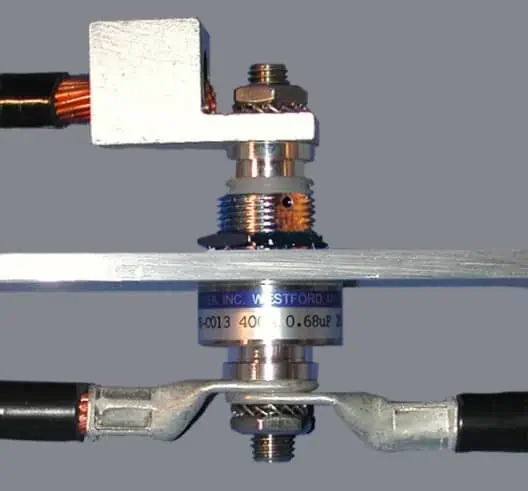

Read MoreProduct Design Spotlight – EMI Filters: High Frequency Filtering Performance

As one of NexTek’s primary product lines, our range of High Current Feedthrough EMI Filters incorporate some advanced design features which make them unique. NexTek HPR Series filters are high-performance, military-grade designs that are built under stringent quality control systems and procedures. This post will focus on the High Frequency Filtering performance of NexTek’s HPR Series…

Read MoreDid You Know? – NexTek Products Meet Many MIL-STDs!

Did you know that NexTek’s wide range of EMC solutions meet a huge number of MIL-STD requirements, from Environmental and Material standards to specific EMC-related Threat Standards. For example, MIL-STD 202 is a comprehensive Environmental Conditions standard which most NexTek products meet to various levels. Although these requirements have nothing to do with Surge or EMI…

Read MoreWebsite Update: Threat Type Pages – EMI/RFI Emissions and Susceptibility

NexTek is proud to announce the addition of two new pages our site, nextek.com. The new sub-pages cover the main Threat Types associated with Electro-Magnetic and Radio Frequency Interference challenges; Emissions and Susceptibility/Vulnerability. NexTek has nearly 30 Years of experience in solving challenging EMC problems and issues, and our standard line of high current feedthrough…

Read More