Product Design Spotlight

Why is Choosing a High Quality Lightning Arrestor Important? – 4 Important Reasons!

Here at NexTek, we take pride in offering a range of coaxial arrestors that are assembled here in the USA to our own designs, using the highest quality materials available and assembled under top notch quality control systems. This is not always the case when it comes to most coaxial protection available on the market today…But Why Does That Matter?…

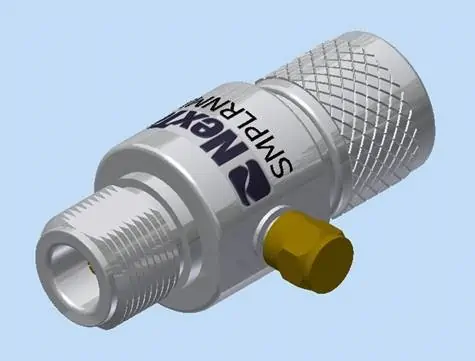

Read MoreNexTek Announces New Product – Type N Sampler Port

Westford, MA – – NexTek, LLC. has been a World -Class leading designer, developer, and manufacturer of standard and custom coaxial surge protectors and high current AC/DC EMI filters for Commercial, Medical, Avionics, SATCOM, Power Supply, Military and Government markets for over 30 years, and proudly announces a new product series for immediate release. The…

Read MoreProduct Bulletin – Integrate RF Surge and Lightning Protection Without Paying a Size or Weight Penalty!

The Neverending Quest For Size Reduction As with most technologies, RF and Wireless system design is an ever-changing and shifting world. As certain technologies or RF bands become popular, others fade away. However, the one ever-present force on the industry is the steady, but relentless, push towards smaller size and better integration over time. Lightning/Surge Protection at the PCB…

Read MoreThree Critical Factors for Comparing and Selecting an EMI Filter

There are three major criterion to pay attention to when comparing different EMI filters and trying to select the proper solution for a given application. Filtering Performance As filtering performance is the reason for any filter to exist in the first place, this is a crucial selection factor. All filters are not created equal, both…

Read MoreWhy Selecting A Rugged EMI/RFI Filter Is Critical For Many Applications

High Current Feedthrough EMI/RFI noise filters are available with many different form factors and circuit designs…From simple C-type filters to L-C and multistage “Pi” filters (C-L-C), there is a wide range of solutions that exist on the market. However, most feedthrough filter designs use technology and construction techniques which make them susceptible to harsh environmental…

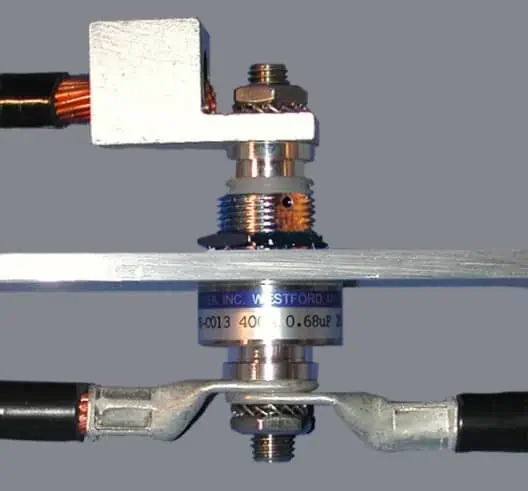

Read MoreCompact Form Factors and Unique Packaging Allows Arrestors To Fit In Tight Spaces – Arrestor Design Spotlight

As one of NexTek’s primary product lines, our range of Coaxial Surge Protectors is designed to cover a wide range of potential application requirements with high-performance, military-grade designs that are built using top-notch quality control systems. One of the many factors that makes NexTek’s line of solutions unique is our use of compact form factor…

Read MoreAre Compact Form Factors Important when Selecting an EMI Filter? – Feedthrough Filter Design Spotlight

Feedthrough EMI/RFI filters are available with many different form factors and circuit designs…From simple C-type filters to L-C and multistage “Pi” filters (C-L-C), there is a wide range of solutions that exist on the market. For many applications where space is at a premium, selecting the most compact filter that will meet requirements can be a critical…

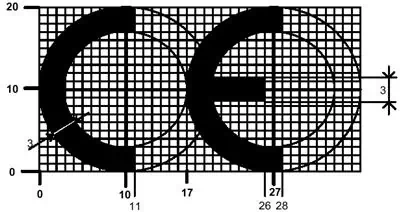

Read MoreFeatured Content & Website Update – NexTek Environmental Policy, REACH & CE Compliance Documents

The most recent uploads to nextek.com include some recently updated Environmental Policy and CE/RoHS/REACH Compliance documents. All standard products from NexTek, LLC. are fully compliant with relevant EU requirements. NexTek minimizes or avoids the use of any hazardous materials wherever possible, and our standard range of products have been fully compliant to EU regulations since…

Read MoreProduct Design Spotlight – EMI Filters: High Frequency Filtering Performance

As one of NexTek’s primary product lines, our range of High Current Feedthrough EMI Filters incorporate some advanced design features which make them unique. NexTek HPR Series filters are high-performance, military-grade designs that are built under stringent quality control systems and procedures. This post will focus on the High Frequency Filtering performance of NexTek’s HPR Series…

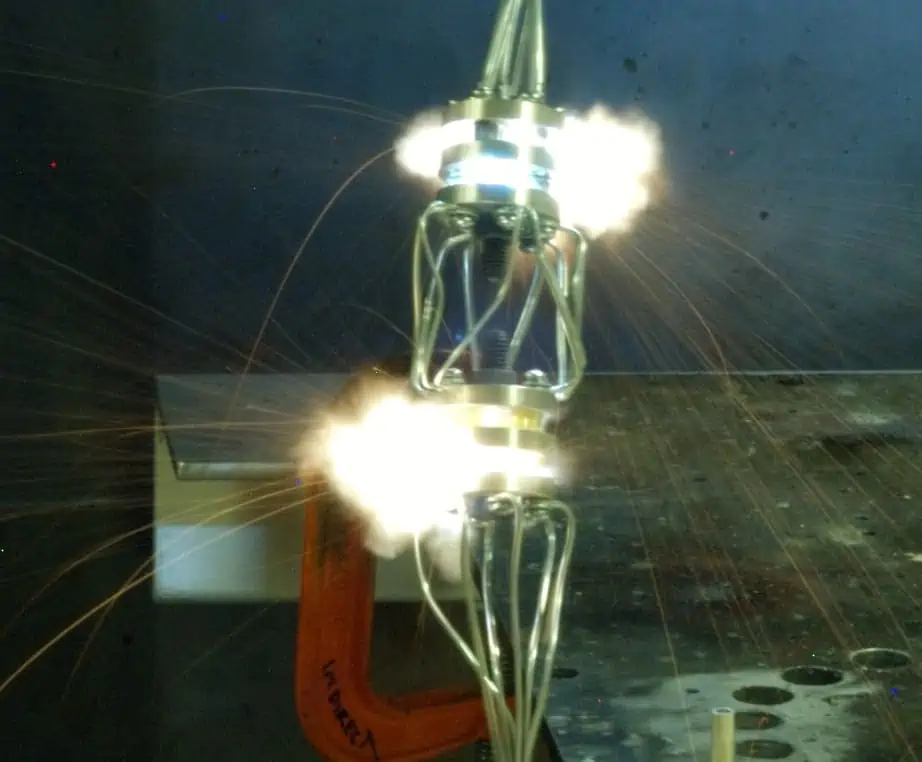

Read MoreProduct Design Spotlight – Arrestors: Surge Ratings

As one of NexTek’s primary product lines, our range of Coaxial Surge Protectors is designed to cover a wide range of potential application requirements with high-performance, military-grade designs that are built using top-notch quality control systems. This post will focus on Surge Ratings and how they relate to coaxial arrestors. Why are Surge Ratings Important?: The…

Read More